Why Dock Levelers Are Essential for Efficient Loading and Unloading Operations

2025-01-03

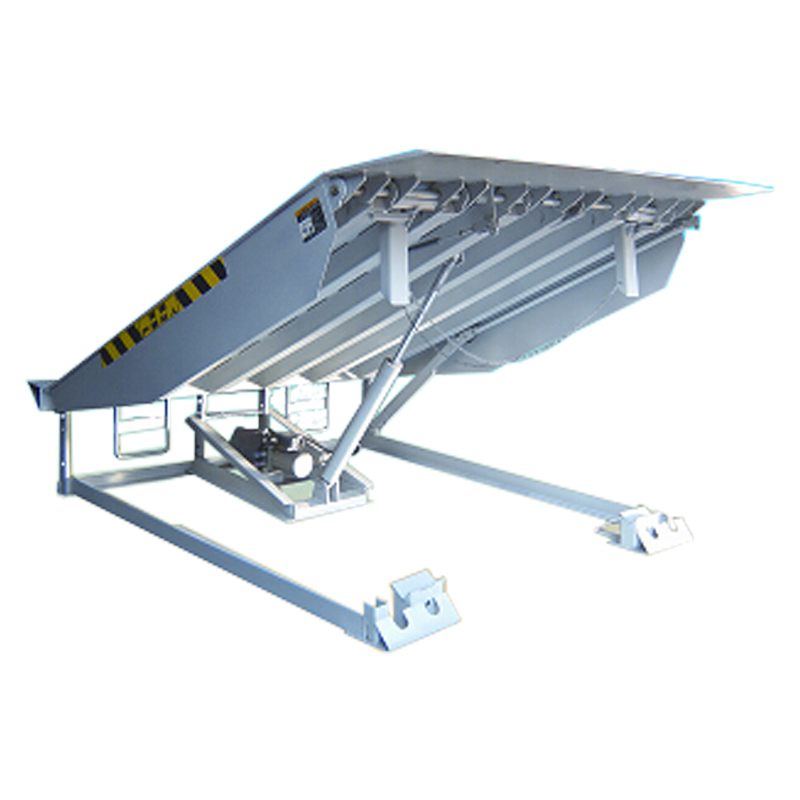

In the world of logistics and warehousing, the efficiency of loading and unloading goods plays a critical role in ensuring timely deliveries and operational success. One of the unsung heroes of this process is the dock leveler. A dock leveler is a piece of equipment that bridges the gap between a loading dock and the back of a truck, allowing for smooth and safe transitions of goods from one to the other. But what exactly is a dock leveler, and why is it so vital in modern logistics?

What Is a Dock Leveler?

A dock leveler is a mechanical or hydraulic platform that adjusts the height of the loading dock to match the height of a truck or trailer. This allows forklifts, pallet jacks, or other loading equipment to move smoothly from the dock to the truck bed, or vice versa, without obstacles or risk of injury. Dock levelers come in various types and designs, including manual, hydraulic, and electronic models, each suited for different operational needs and levels of automation.

The key purpose of a dock leveler is to provide a safe and efficient transition for goods being loaded or unloaded, ensuring that vehicles and warehouses can maintain smooth, continuous workflows with minimal risk of delays or accidents.

The Importance of Dock Levelers in Logistics

1. Improved Efficiency and Speed

One of the primary benefits of a dock leveler is that it dramatically improves the efficiency of loading and unloading operations. By creating a seamless bridge between the loading dock and the truck, workers can quickly load and unload cargo, which reduces downtime and increases productivity. This is particularly important in high-volume warehouses or distribution centers, where time is money, and delays can have a ripple effect on the entire operation.

With a dock leveler, workers don’t need to manually adjust ramps or deal with uneven surfaces, which speeds up the entire process. This efficiency ultimately helps businesses handle more shipments per day, improving throughput and profitability.

2. Enhancing Worker Safety

Dock levelers also play a vital role in improving safety in the workplace. Without a proper leveling system, employees are exposed to several hazards, including:

- Trips and falls due to uneven surfaces

- Injuries from forklifts or other equipment if they are forced to navigate over uneven gaps

- Strained muscles from lifting or pushing items across an uneven surface

By ensuring that the loading dock is level with the truck bed, dock levelers minimize these risks and create a safer working environment for warehouse staff. In fact, many workplace safety regulations require the use of dock levelers to prevent accidents related to loading dock operations.

3. Protecting Goods from Damage

In addition to improving worker safety, dock levelers also protect the goods being handled. Without a dock leveler, there is a higher risk of damaging cargo, especially fragile items, as they may need to be manually lifted over uneven surfaces or between mismatched heights. Forklifts and other machinery also risk damaging the truck or warehouse doors if there is no stable, level platform for loading.

Dock levelers reduce the chances of goods getting damaged during the loading and unloading process by creating a consistent and safe height match, which ensures smooth and controlled transitions for all types of cargo.

4. Versatility in Operations

Dock levelers are designed to accommodate a wide variety of vehicles, ranging from standard trucks to specialized containers and trailers. With adjustable heights, they can handle different vehicle types and ensure that the loading dock stays functional, no matter what is being loaded. Some models even come with additional features such as telescoping or lip extensions to handle uneven or sloped trailer beds more easily.

Whether a business handles small packages, large pallets, or sensitive equipment, the versatility of a dock leveler makes it an invaluable asset for adapting to various goods and operational needs.

5. Weather Protection

Another advantage of dock levelers, particularly in harsh climates, is that they help shield loading dock areas from weather-related issues. A properly installed dock leveler prevents the intrusion of rain, snow, or wind from entering the warehouse while loading or unloading trucks. This is crucial for keeping products protected from the elements and maintaining a safe, comfortable working environment inside the warehouse.

Types of Dock Levelers

There are several types of dock levelers available, each with its unique features to cater to different needs:

- Mechanical Dock Levelers: These are manually operated levelers, typically requiring workers to use a pull chain to adjust the platform height. Mechanical levelers are cost-effective and easy to maintain, making them ideal for smaller warehouses or those with low traffic.

- Hydraulic Dock Levelers: Powered by hydraulic systems, these levelers provide easier and more efficient height adjustments. They require less physical effort from operators and can be adjusted with the push of a button. Hydraulic dock levelers are ideal for busy, high-traffic facilities where speed and ease of use are crucial.

- Pneumatic Dock Levelers: Using air pressure instead of hydraulic fluids, pneumatic dock levelers provide similar benefits to hydraulic models but are ideal for industries where cleanliness and safety are a concern, such as food processing or pharmaceutical warehouses.

- Edge of Dock Levelers: These compact devices are mounted directly at the edge of the dock and are generally more affordable than full-sized dock levelers. They are a great option for smaller warehouses with lower volumes of traffic.

- Vertical Lift Dock Levelers: These levelers offer adjustable height capabilities, especially useful when dealing with a wide range of vehicle heights. Vertical lift levelers are typically found in specialized or high-demand industries.

Conclusion

Dock levelers are an essential piece of equipment in any warehouse or distribution facility, providing significant benefits in terms of safety, efficiency, and operational continuity. By creating a smooth transition between the loading dock and trucks, these devices help streamline the loading and unloading process, prevent injury and product damage, and protect the overall efficiency of logistics operations.

Whether you are looking to improve warehouse operations, enhance worker safety, or protect the goods you are transporting, investing in the right type of dock leveler can make a world of difference. With the right equipment in place, businesses can ensure that their loading docks operate smoothly, efficiently, and safely, day in and day out.