What Are the Benefits of Using Anti-Static PFA Tubes in Sensitive Applications?

2024-11-06

In various industries, especially those dealing with electronics, pharmaceuticals, and chemicals, the prevention of static electricity build-up is crucial. Static discharge can lead to significant issues, including equipment damage, product contamination, and safety hazards. This is where anti-static PFA (Perfluoroalkoxy alkane) tubes come into play. But what are the benefits of using anti-static PFA tubes in sensitive applications? In this blog, we will explore the properties of these tubes and how they contribute to safer, more efficient operations.

What Are Anti-Static PFA Tubes?

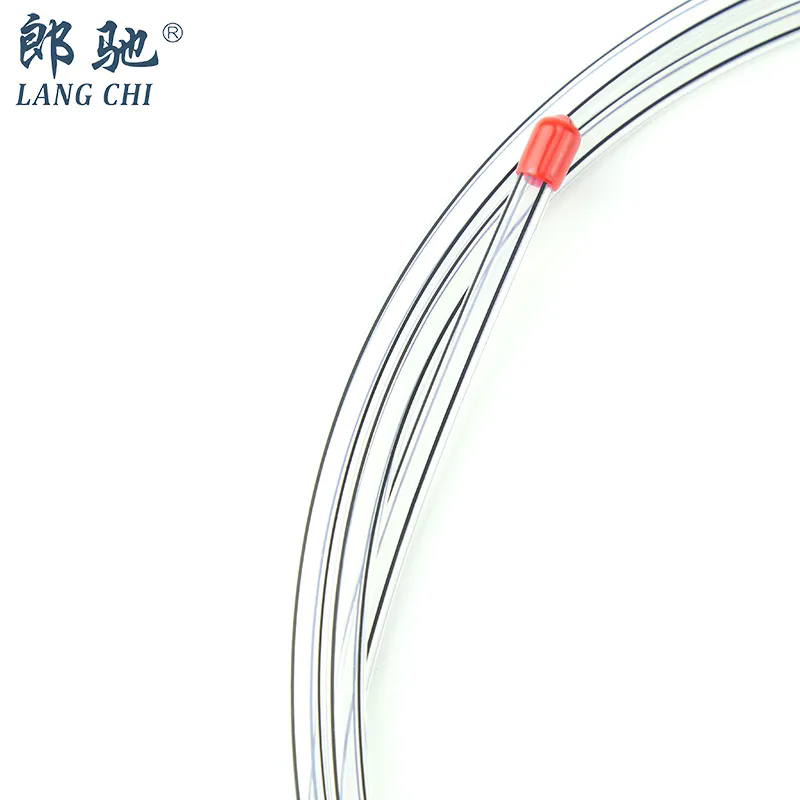

Anti-static PFA tubes are specialized tubing made from PFA, a high-performance fluoropolymer. This material is known for its excellent chemical resistance, thermal stability, and low friction properties. The "anti-static" characteristic is achieved by incorporating additives into the PFA, which helps to dissipate static charges and minimize the risk of electrostatic discharge (ESD). These tubes are commonly used in environments where static electricity can pose a threat to sensitive equipment or products.

How Do Anti-Static PFA Tubes Enhance Safety?

1. Prevention of Electrostatic Discharge: One of the primary benefits of anti-static PFA tubes is their ability to prevent electrostatic discharge. This is particularly important in industries such as electronics manufacturing, where even a minor static discharge can damage sensitive components. By using anti-static PFA tubes, companies can significantly reduce the risk of such occurrences.

2. Improved Product Quality: In the pharmaceutical and food industries, maintaining product integrity is vital. Static electricity can attract dust, debris, and contaminants to surfaces, compromising product quality. Anti-static PFA tubes help minimize these risks, ensuring that the products remain uncontaminated throughout the handling and transportation processes.

3. Enhanced Worker Safety: Static electricity can pose safety risks in environments where flammable materials are present. By utilizing anti-static PFA tubes, companies can create a safer workplace by reducing the likelihood of static-induced fires or explosions.

What Are the Key Properties of Anti-Static PFA Tubes?

1. Chemical Resistance: PFA is highly resistant to a wide range of chemicals, making it suitable for transporting aggressive fluids without degrading. This property is essential in industries such as chemicals and pharmaceuticals, where exposure to harsh substances is common.

2. Thermal Stability: Anti-static PFA tubes can withstand a wide temperature range, typically from -200°C to +260°C. This thermal stability allows them to perform effectively in both high and low-temperature applications, ensuring reliability in various environments.

3. Flexibility and Transparency: These tubes are flexible, making them easy to install and maneuver in tight spaces. Their transparency also allows for visual monitoring of the fluid flow, which is crucial in many applications.

How Do Anti-Static PFA Tubes Compare to Other Materials?

When considering tubing options for sensitive applications, it's important to understand how anti-static PFA tubes stack up against other materials:

- Versus PVC: While PVC tubing is common, it does not provide the same level of chemical resistance and may not be suitable for high-temperature applications. Anti-static PFA tubes, on the other hand, offer superior performance in both areas.

- Versus PTFE: PTFE (Polytetrafluoroethylene) is another fluoropolymer known for its excellent chemical resistance. However, PTFE tubes may not always have anti-static properties. Anti-static PFA tubes combine the benefits of PFA with the added advantage of static dissipation.

What Applications Benefit Most from Anti-Static PFA Tubes?

1. Electronics Manufacturing: In environments where static-sensitive components are handled, anti-static PFA tubes are essential for safe transport and processing.

2. Pharmaceutical Production: These tubes help maintain product purity and prevent contamination during the transportation of active pharmaceutical ingredients (APIs) and other sensitive materials.

3. Chemical Processing: Anti-static PFA tubes are used in chemical laboratories and processing facilities to safely transfer aggressive fluids without risk of static-related incidents.

Conclusion: Are Anti-Static PFA Tubes the Right Choice for Your Application?

In conclusion, anti-static PFA tubes offer numerous benefits that make them an ideal choice for sensitive applications across various industries. Their ability to prevent electrostatic discharge, combined with their chemical resistance and thermal stability, enhances safety, product quality, and operational efficiency. As industries continue to prioritize safety and performance, the use of anti-static PFA tubes will undoubtedly become increasingly important. By considering the unique properties and advantages of these tubes, businesses can make informed decisions that protect both their products and their operations.