Understanding Excavator Link Assembly: The Backbone of Heavy Machinery Performance

2024-10-17

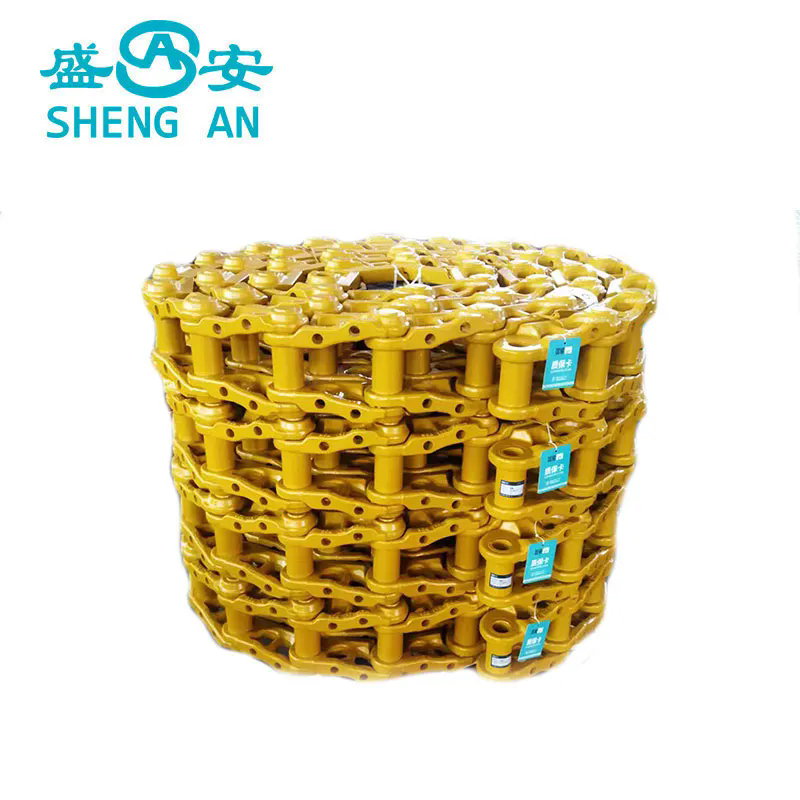

In the world of construction and excavation, excavators play a pivotal role, and at the heart of these machines are their link assemblies. The Excavator Link Assembly (Link Assy) is a crucial component that ensures the smooth movement and durability of the machine’s boom, arm, and bucket. Without a reliable link assembly, even the most powerful excavators would struggle with precision and efficiency.

In this blog, we’ll dive into what an excavator link assembly is, its importance, key components, and tips for maintenance to extend the life of your machinery.

What is an Excavator Link Assembly?

An excavator link assembly refers to the interconnected mechanical parts that connect the bucket, boom, and arm of an excavator. It ensures that the machine’s movements are smooth, controlled, and precise during heavy-duty operations like digging, lifting, or loading.

These link assemblies must withstand immense stress, making them essential for achieving optimal performance and productivity on construction sites.

Key Components of an Excavator Link Assembly

1. Link Arm (Dogbone Link):

- A heavy-duty steel component that connects the bucket to the boom or arm, facilitating coordinated movement.

- It bears the tensile and compressive forces generated during digging or loading operations.

2. Bushings:

- Cylindrical linings within the links that reduce friction between moving parts.

- High-quality bushings are essential for ensuring smooth motion and preventing wear.

3. Pins:

- Hardened steel pins are inserted through the bushings to hold the links together.

- These pins are critical for maintaining alignment and mobility of the bucket and arm assembly.

4. Seals and Grease Fittings:

- Grease fittings ensure proper lubrication to prevent wear between moving parts.

- Seals keep dirt, debris, and water out, protecting the internal components from damage.

5. Side Plates and Brackets:

- These provide additional support and alignment for the link assembly, especially under heavy loads.

Importance of Excavator Link Assemblies

1. Smooth Operation:

The link assembly ensures that the bucket and arm respond accurately to operator commands, facilitating precise digging, lifting, and movement.

2. Durability Under Load:

These assemblies are designed to withstand extreme pressure and tough environments, including construction sites, quarries, and mining operations.

3. Reduced Downtime:

High-quality link assemblies, when properly maintained, prevent frequent breakdowns and costly repairs, maximizing uptime.

4. Versatility:

Excavators are used for various tasks like excavating trenches, loading materials, and demolishing structures. The link assembly ensures the machine’s versatility by providing stability and control for different attachments.

Maintenance Tips for Excavator Link Assemblies

To ensure your excavator performs efficiently and lasts longer, it’s essential to maintain the link assembly properly. Here are some maintenance tips:

1. Regular Lubrication:

- Ensure all pins and bushings are adequately greased to reduce friction and wear.

- Use the appropriate lubricant for your machine’s working conditions (e.g., extreme cold or heat).

2. Inspect for Wear and Tear:

- Regularly check pins, bushings, and seals for wear or damage.

- Look for signs of looseness or misalignment, which may indicate worn components.

3. Replace Damaged Parts Promptly:

- A small issue, like a worn pin, can lead to larger failures if left unattended.

- Use OEM parts to ensure compatibility and durability.

4. Keep the Assembly Clean:

- Remove dirt, mud, and debris that can clog grease fittings or cause wear over time.

5. Monitor Alignment:

- Misalignment between the arm, bucket, and boom can increase stress on the link assembly.

- Regularly inspect the link arm and pins to ensure proper alignment.

How to Choose a Quality Excavator Link Assembly

When selecting a replacement link assembly for your excavator, consider the following factors:

1. Material Strength:

- Look for assemblies made from high-strength steel to ensure durability.

- Reinforced materials resist corrosion and cracking under pressure.

2. Compatibility:

- Ensure the assembly matches your excavator’s make and model.

- Some machines may require customized link assemblies for specific attachments.

3. Brand and Manufacturer Reputation:

- Choose parts from reliable manufacturers known for quality components.

- OEM parts often provide the best fit and longevity.

4. Warranty and Support:

- Opt for products that come with a warranty to protect your investment.

- Check if the supplier offers technical support or installation services.

Conclusion

The Excavator Link Assembly is a vital component that directly influences the performance, precision, and longevity of heavy machinery. Proper maintenance and the use of high-quality components can significantly reduce operational downtime and increase productivity on the job site.

Whether you’re a contractor managing a fleet or an equipment owner with a single excavator, investing in quality link assemblies and staying on top of regular maintenance will ensure your machine operates smoothly and efficiently for years to come.

By understanding the role and care of link assemblies, you can ensure your excavator delivers reliable performance no matter the terrain or task.