The Versatility and Strength of Steel Wire Ropes

2025-02-07

Steel wire ropes are some of the most essential components used in various industries worldwide. From heavy-duty construction to marine applications, steel wire ropes play a vital role in ensuring safety, efficiency, and durability. Known for their impressive strength, flexibility, and resistance to wear and tear, these ropes are indispensable in a wide array of operations where load-bearing and movement are critical.

What is a Steel Wire Rope?

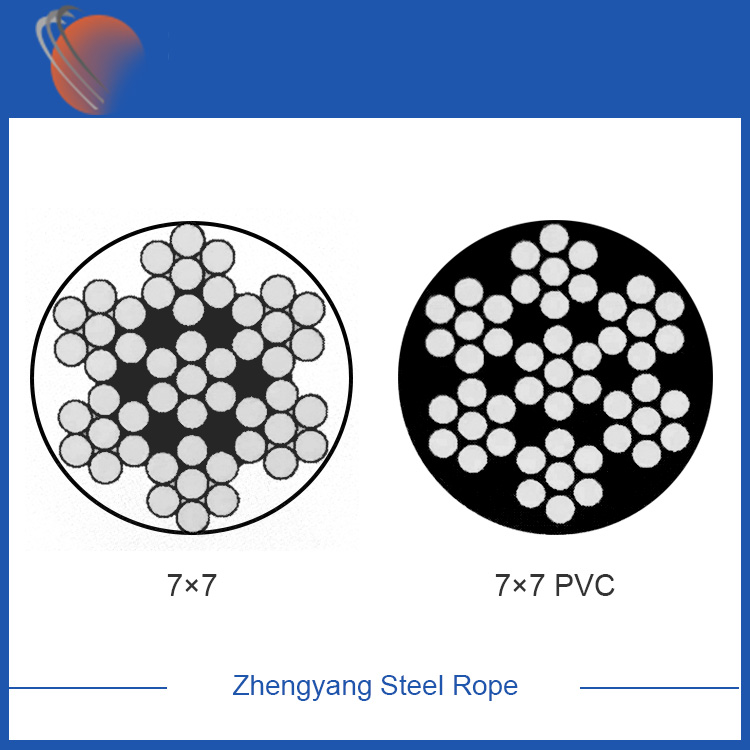

A steel wire rope consists of multiple strands of steel wires twisted together to form a single rope. The strands themselves are composed of individual steel wires, and the construction of these ropes can vary based on the specific requirements of the application. Steel wire ropes are available in different grades and configurations, and they are typically coated to provide additional protection against corrosion and environmental factors.

Steel wire ropes are often chosen for their superior tensile strength and ability to handle heavy loads under extreme conditions. The wire ropes can be manufactured in various constructions, such as 6x19, 6x36, or 8x19, depending on the number of strands and wires per strand. The choice of construction directly influences the rope's flexibility, strength, and resistance to wear.

Key Properties of Steel Wire Ropes

1. Strength and Durability

Steel wire ropes are known for their remarkable strength-to-weight ratio. The high tensile strength of steel ensures that these ropes can bear heavy loads and resist significant stress without breaking or stretching. This makes them ideal for use in heavy lifting, transportation, and industrial applications.

2. Flexibility

Despite their strength, steel wire ropes are also flexible, allowing them to bend and stretch without losing their integrity. This flexibility makes them suitable for applications where ropes need to move or wrap around pulleys, drums, and other mechanisms.

3. Resistance to Wear and Corrosion

Steel wire ropes are highly resistant to wear and tear, especially when coated with materials like galvanized steel, stainless steel, or polymer coatings. These coatings provide added protection against corrosion, making the ropes ideal for harsh environments such as marine settings or high-moisture conditions.

4. High Friction Resistance

The design of steel wire ropes offers excellent friction resistance, reducing the likelihood of slippage and increasing the grip between the rope and the surfaces it interacts with. This makes them reliable for hoisting, lifting, and securing heavy objects.

5. Long Lifespan

Steel wire ropes are known for their longevity. With proper maintenance and care, they can last for many years, even under harsh operating conditions. Regular inspection for wear and tear can further extend their service life.

Applications of Steel Wire Ropes

Steel wire ropes are used in a variety of industries and applications where strength, flexibility, and durability are essential:

1. Construction

In construction, steel wire ropes are used for hoisting heavy loads, securing scaffolding, and operating cranes. These ropes play a vital role in lifting large materials like steel beams, concrete blocks, and machinery parts, ensuring safety and stability during the construction process.

2. Marine and Offshore

Steel wire ropes are heavily used in the marine and offshore industries. They are used in applications such as ship mooring, anchoring, lifting equipment, and offshore drilling rigs. Due to their resistance to corrosion and ability to withstand harsh saltwater environments, steel wire ropes are ideal for these applications.

3. Mining and Excavation

In the mining industry, steel wire ropes are used in elevators, conveyors, and lifting equipment to transport materials from underground to the surface. These ropes must endure the harsh conditions of mining sites, where they are exposed to dust, dirt, and heavy weights.

4. Aerospace and Aviation

Steel wire ropes are used in aircraft control systems, such as elevator cables and rudder controls. The ropes must be lightweight, yet capable of handling precise movements and heavy loads while maintaining flexibility.

5. Cranes and Lifting Equipment

Steel wire ropes are the backbone of crane operations. Whether used in construction sites, ports, or shipping yards, the ropes support the lifting and lowering of heavy containers, equipment, and materials. Their strength and durability ensure that the cranes can perform heavy-duty operations without failure.

6. Sports and Recreation

Steel wire ropes are also used in elevators for ski lifts, zip lines, and climbing ropes. In these cases, safety and strength are paramount, and steel wire ropes provide the necessary support for outdoor activities and recreation.

7. Railroads

In the railway industry, steel wire ropes are used in railway signal systems, train control systems, and for lifting heavy loads during the construction and maintenance of tracks.

Choosing the Right Steel Wire Rope

Selecting the correct steel wire rope for a specific application involves considering several factors:

- Load capacity: Determine the weight the rope will need to support. This will influence the diameter and construction type of the rope.

- Environmental factors: Consider whether the rope will be exposed to moisture, chemicals, or extreme temperatures. In such cases, ropes with corrosion-resistant coatings or made from stainless steel may be required.

- Flexibility vs. strength: Depending on the application, you may need a rope that balances flexibility with strength. Some applications may prioritize flexibility, while others require maximum load-bearing capacity.

Maintenance and Care

While steel wire ropes are known for their durability, regular inspection and maintenance are crucial to ensuring their longevity. Regularly check for signs of wear, such as broken wires, flattened areas, or corrosion. Proper lubrication can also help reduce friction and extend the rope’s service life.

Conclusion

Steel wire ropes are indispensable in numerous industries due to their strength, durability, and versatility. From construction and mining to marine and aerospace applications, these ropes are designed to handle extreme conditions while ensuring safety and efficiency. As technology and materials continue to evolve, steel wire ropes will remain at the core of heavy-duty applications where reliability is paramount. With proper maintenance, steel wire ropes can continue to serve as a trusted solution for many years, enabling industries to move heavier loads and perform more efficiently.