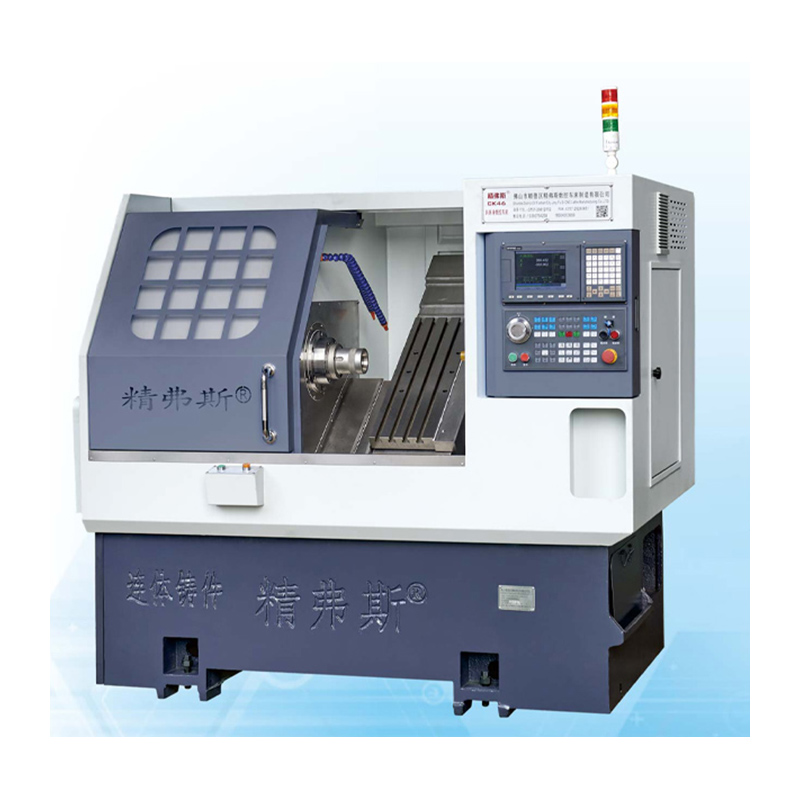

Slant-bed CNC Lathe: Precision, Efficiency, and Stability in Modern Machining

2025-07-03

The Slant-bed CNC latheis a powerful and highly efficient machine tool used in the precision manufacturing of metal parts. Unlike traditional flat-bed lathes, the slant-bed design features an inclined structure, which provides enhanced rigidity, chip removal, and operator accessibility. Widely used in industries such as aerospace, automotive, medical devices, and general engineering, the slant-bed CNC lathe has become a cornerstone of high-performance turning operations.

What Is a Slant-bed CNC Lathe?

A slant-bed CNC (Computer Numerical Control) lathe is a type of turning machine where the bed is angled—typically at 30°, 45°, or even 60°—relative to the horizontal plane. This slanted structure allows gravity to assist in the removal of metal chips and improves cutting performance, especially in high-speed or heavy-duty operations.

The CNC control system automates the machine's movement and tool operations, enabling the production of highly precise components with minimal manual intervention.

Key Advantages of Slant-bed CNC Lathes

1. Superior Chip Evacuation:The inclined bed allows chips to fall away naturally, reducing heat buildup and improving surface finish.

2. Enhanced Rigidity and Stability:The slanted design supports better force distribution during cutting, which minimizes vibration and increases tool life.

3. Improved Accessibility:The angled layout makes it easier for operators to change tools, load materials, and perform inspections.

4. High Precision and Repeatability:CNC programming ensures consistent accuracy even in complex or multi-step operations.

5. Space Efficiency:The compact footprint and integrated systems make slant-bed lathes ideal for both small shops and large production facilities.

Applications of Slant-bed CNC Lathes

Automotive Parts:Engine components, shafts, and bushings.

Aerospace:High-precision fittings, connectors, and structural parts.

Medical Equipment:Surgical tools, orthopedic implants, and dental components.

General Manufacturing:Fasteners, threaded parts, couplings, and custom turned products.

Main Components of a Slant-bed CNC Lathe

Slanted Bed:Provides structural support and ensures effective chip flow.

CNC Control Unit:Controls machine movements with programmed commands (G-code).

Spindle:Rotates the workpiece with high speed and accuracy.

Tool Turret:Holds multiple tools for automated changeover during operation.

Tailstock or Sub-Spindle (optional):Supports long parts or enables dual-end machining.

Choosing the Right Slant-bed CNC Lathe

When selecting a slant-bed CNC lathe, consider:

Workpiece Size:Ensure the lathe supports the maximum turning length and diameter required.

Number of Tool Stations:More tools enable complex parts to be completed in a single setup.

Control System Compatibility:Choose a system (like FANUC, Siemens, or Mitsubishi) that matches your programming preferences.

Automation Options:For mass production, consider bar feeders, parts catchers, or robotic loading systems.

Conclusion

The slant-bed CNC lathe represents a blend of advanced engineering and intelligent automation. Its angled design improves machining accuracy, tool life, and operational ease, making it an ideal choice for modern manufacturing. Whether you're producing small precision parts or large, complex components, a slant-bed CNC lathe offers the performance and reliability needed in today’s competitive industrial environment.