Key Properties of BR Rubber Compound

2024-05-28

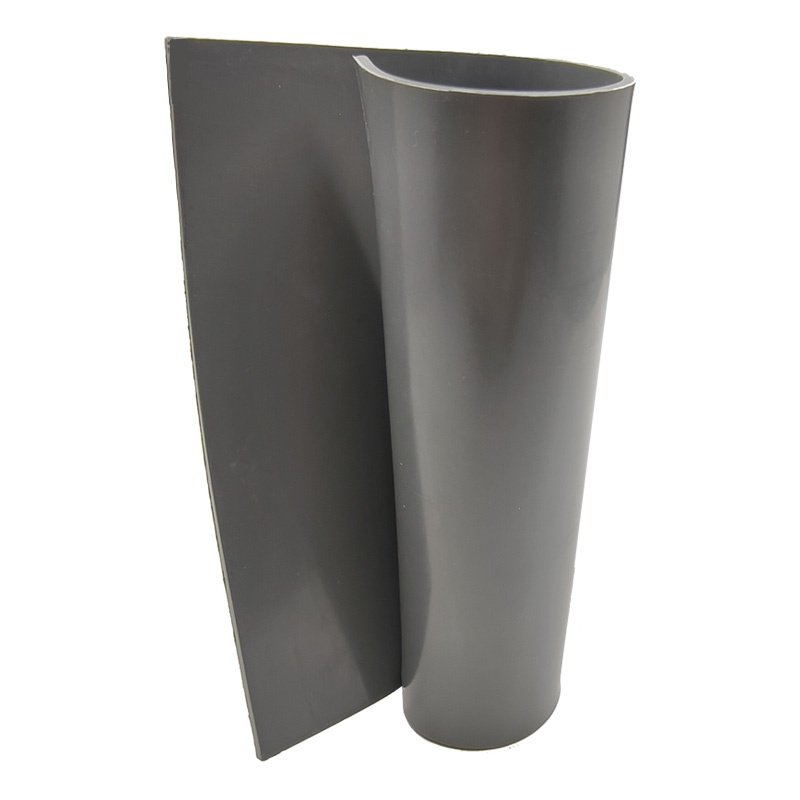

BR rubber compound refers to a synthetic rubber compound primarily composed of butadiene rubber (BR). Butadiene rubber is a synthetic polymer derived from the monomer butadiene. It is commonly used in the production of various rubber products due to its desirable properties, including high resilience, abrasion resistance, and low temperature flexibility.

Key Properties of BR Rubber Compound:

1. High Resilience: BR rubber offers excellent rebound resilience, making it suitable for applications requiring elasticity and bounce.

2. Abrasion Resistance: It exhibits good resistance to wear and abrasion, making it suitable for use in tires, conveyor belts, and other high-wear applications.

3. Low Temperature Flexibility: BR rubber remains flexible and pliable even at low temperatures, making it ideal for cold weather applications.

4. Tear Resistance: It has good tear strength and resistance to tearing, contributing to the durability of rubber products.

5. Electrical Insulation: BR rubber exhibits electrical insulating properties, making it suitable for use in electrical insulation components and applications.

6. Compatibility with Fillers and Additives: BR rubber can be easily compounded with various fillers, reinforcing agents, and additives to modify its properties for specific applications.

Applications of BR Rubber Compound:

1. Tires: BR rubber is commonly used in tire manufacturing as a component of tire treads, providing excellent traction, durability, and abrasion resistance.

2. Conveyor Belts: It is used in the production of conveyor belts for industrial material handling applications due to its abrasion resistance and flexibility.

3. Footwear: BR rubber compounds are used in the manufacture of shoe soles and outsoles, providing cushioning, durability, and traction.

4. Seals and Gaskets: BR rubber is utilized in the production of seals, gaskets, and O-rings for various industrial and automotive applications due to its sealing properties and resilience.

5. Vibration Dampers: It is used in the production of vibration dampers and isolation mounts to absorb shocks and vibrations in machinery and automotive systems.

6. Hoses and Tubing: BR rubber compounds are used in the manufacture of hoses, tubing, and other flexible rubber products for fluid transfer applications due to their flexibility and durability.

7. Sporting Goods: BR rubber is used in the production of sporting goods such as balls, mats, and grips due to its resilience, durability, and abrasion resistance.

Manufacturing Process:

The manufacturing process of BR rubber compound involves compounding various ingredients, including butadiene rubber, fillers, reinforcing agents, plasticizers, and vulcanizing agents. These ingredients are mixed together in a rubber mixer or mill to achieve a homogeneous mixture. The compound is then processed through various shaping and curing methods, such as molding, extrusion, or calendering, to produce the final rubber product with the desired properties.

Environmental Considerations:

While BR rubber offers many desirable properties and is widely used in various applications, it is important to consider its environmental impact. Synthetic rubber compounds, including BR rubber, are derived from petrochemical sources and may contribute to environmental pollution during manufacturing and disposal. Efforts to minimize waste generation, improve energy efficiency, and explore sustainable alternatives are ongoing in the rubber industry to mitigate environmental impacts.

BR rubber compound is a versatile material with a wide range of applications across industries due to its resilience, abrasion resistance, and flexibility. By understanding its properties, applications, and manufacturing process, manufacturers can effectively utilize BR rubber compounds to produce high-quality rubber products for various industrial, automotive, and consumer applications.