Key aspects involved in the injection molding process for auto interior trim

2023-12-15

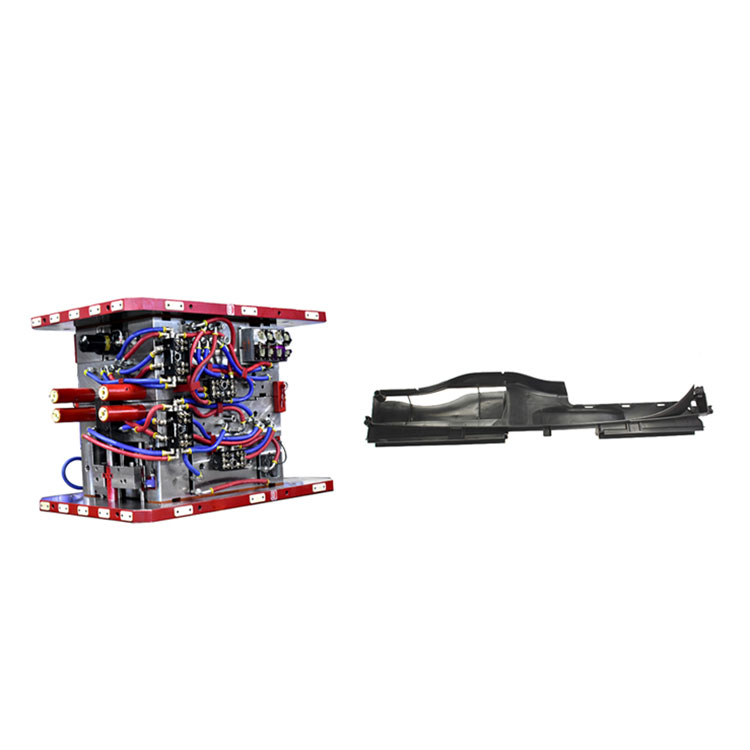

Designing and manufacturing injection molds for auto interior trim components involves several considerations to ensure quality, precision, and efficiency. Auto interior trim components can include items like dashboard panels, door panels, center consoles, and other interior features. Here's an overview of the key aspects involved in the injection molding process for auto interior trim:

1. Material Selection:

- Choose a plastic material that meets the specific requirements for interior trim components. Common materials include ABS (Acrylonitrile Butadiene Styrene), PP (Polypropylene), and PC-ABS (Polycarbonate-ABS) blends.

2. Mold Design:

- Geometry and Detailing: Design the mold to replicate the intricate details of the interior trim component. This includes textures, logos, and any other surface features.

- Multi-Cavity Molds: For high-volume production, multi-cavity molds can be used to produce multiple parts in each molding cycle.

3. Quality and Aesthetics:

- Surface Finish: Achieving the desired surface finish is crucial for interior components, as they are visible and contribute to the overall aesthetics of the vehicle.

- Color Matching: Ensure that the injection molding process can achieve consistent color matching for interior trim components.

4. Tolerance and Fitment:

- Precision: Interior trim components often require tight tolerances to ensure proper fit and finish within the vehicle.

- Assembly Considerations: If the interior trim components are part of a larger assembly, design the molds with features that facilitate easy assembly.

5. Injection Molding Machine and Process:

- Machine Size: Select an injection molding machine with an appropriate clamping force and shot size for the size and complexity of the interior trim components.

- Optimized Process Parameters: Fine-tune injection parameters such as temperature, pressure, and cooling times to optimize the molding process for the chosen material.

6. Tooling and Maintenance:

- Regular Maintenance: Conduct regular maintenance on the molds to ensure longevity and consistent quality.

- Tooling Material: Choose durable materials for the mold to withstand the stresses of high-volume production.

7. Automation and Efficiency:

- Robotics: Implement automation for tasks such as part removal, inspection, and packaging to improve efficiency and reduce cycle times.

8. Regulatory Compliance:

- Ensure that the manufacturing process and materials used comply with relevant automotive industry standards and regulations.

By addressing these considerations, manufacturers can produce high-quality auto interior trim components through the injection molding process. Keep in mind that collaboration between design, engineering, and manufacturing teams is crucial to achieving the desired results.