Functions of Mesh Grease Filters

2024-04-26

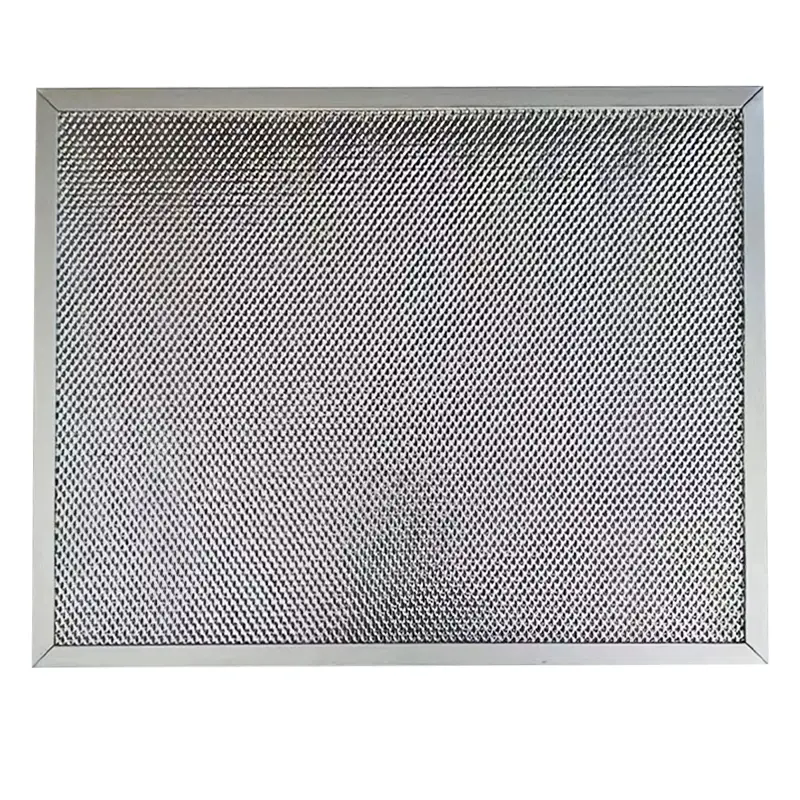

A mesh grease filter, also known as a grease trap filter or a grease baffle filter, is a component commonly used in commercial kitchen exhaust systems to capture grease and prevent it from entering ventilation ducts and fans. These filters play a crucial role in maintaining indoor air quality, preventing fire hazards, and ensuring the efficiency of kitchen exhaust systems.

Here are some key features and functions of mesh grease filters:

1. Grease Capture: Mesh grease filters are designed to capture grease, oil, and other airborne contaminants generated during cooking processes. They typically consist of multiple layers of fine mesh or baffles arranged in a staggered pattern to maximize surface area and trapping efficiency.

2. Airflow: Mesh grease filters allow air to pass through while trapping grease particles, ensuring that the kitchen exhaust system can effectively remove smoke, steam, and odors from the cooking area. Proper airflow is essential for maintaining a comfortable and safe working environment in commercial kitchens.

3. Fire Protection: Grease buildup in kitchen exhaust ducts and ventilation systems poses a significant fire hazard. Mesh grease filters help prevent the accumulation of grease in these areas, reducing the risk of grease fires and ensuring compliance with fire safety regulations.

4. Easy Maintenance: Mesh grease filters are designed for easy removal and cleaning to maintain their effectiveness over time. Depending on the frequency and intensity of cooking operations, filters may need to be cleaned or replaced regularly to prevent clogging and maintain optimal airflow.

5. Compatibility: Mesh grease filters are available in various sizes and configurations to fit different types of commercial kitchen hoods and exhaust systems. They can be installed in canopy hoods, ductless hoods, island hoods, and other ventilation setups commonly found in restaurants, cafeterias, and other food service establishments.

6. Material: Grease filters are typically made from durable materials such as stainless steel or aluminum to withstand the harsh conditions of commercial kitchen environments. Stainless steel filters are preferred for their corrosion resistance and longevity.

7. Compliance: Mesh grease filters must meet relevant safety and hygiene standards, such as those set by organizations like the National Fire Protection Association (NFPA) and local building codes. Regular inspection and maintenance of grease filters are essential to ensure compliance and prevent potential safety hazards.

Overall, mesh grease filters are essential components of commercial kitchen ventilation systems, providing effective grease capture, fire protection, and indoor air quality control to ensure a safe and healthy environment for kitchen staff and patrons.