Benefits of Tungsten Steel Drill Point Die

2024-07-13

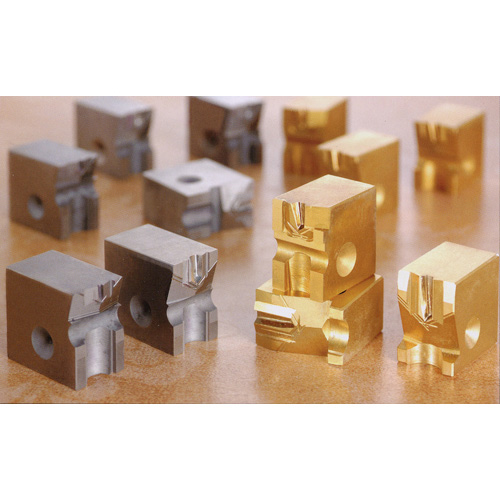

A tungsten steel drill point die is a specialized tool used in manufacturing and machining processes to create precise and durable drill points on various materials. Here's a detailed overview:

Composition and Properties:

1. Tungsten Steel:

- Composition: Tungsten steel, also known as high-speed steel (HSS) or tungsten carbide, is an alloy composed primarily of tungsten, carbon, and cobalt.

- Properties: Known for its exceptional hardness, high-temperature resistance, and wear resistance. It can maintain a sharp edge even at high temperatures, making it ideal for cutting and drilling applications.

2. Drill Point Die:

- Purpose: Used to shape and sharpen the points of drill bits, ensuring they have the correct geometry for efficient drilling.

- Design: Typically designed with specific angles and profiles to create precise drill points suitable for different materials and applications.

Applications:

1. Manufacturing:

- Used in the production of drill bits for various industries, including automotive, aerospace, and construction.

- Ensures that drill bits have consistent quality and performance.

2. Machining:

- Employed in machining shops to maintain and sharpen drill bits, extending their useful life.

- Helps in achieving accurate and clean holes in different materials like metal, plastic, and wood.

3. Tool and Die Making:

- Integral in the tool and die industry for creating precise cutting tools and dies.

- Used for maintaining the sharpness and precision of tools used in stamping, cutting, and forming operations.

Benefits:

1. Precision:

- Provides accurate and consistent drill point geometry, crucial for high-quality drilling.

- Reduces the likelihood of drill bit breakage and ensures clean, precise holes.

2. Durability:

- Tungsten steel’s hardness and wear resistance result in long-lasting dies that require less frequent replacement.

- Capable of withstanding the rigors of high-speed and high-temperature drilling operations.

3. Efficiency:

- Sharpens drill bits quickly and accurately, improving operational efficiency.

- Reduces downtime in manufacturing and machining processes by maintaining tool sharpness.

Types of Drill Points:

1. Standard Point:

- Typically has a 118-degree angle.

- Suitable for general-purpose drilling in a variety of materials.

2. Split Point:

- Features a chisel-shaped tip that reduces walking and increases precision.

- Often has a 135-degree angle, making it ideal for harder materials like metal.

3. Brad Point:

- Designed for woodworking, featuring a central point and spurs for clean, precise holes.

- Ensures accurate positioning and minimizes splintering.

Maintenance and Care:

1. Regular Inspection:

- Check for signs of wear, chipping, or damage to ensure the die remains effective.

- Regular maintenance can extend the life of the die and ensure consistent performance.

2. Proper Storage:

- Store in a clean, dry environment to prevent rust and corrosion.

- Keep the die covered or in a protective case when not in use.

3. Lubrication:

- Use appropriate lubricants during use to reduce friction and wear.

- Ensure the die and drill bits are clean and free from debris before use.

Conclusion:

A tungsten steel drill point die is a vital tool in the manufacturing and machining industries, providing precision, durability, and efficiency in the creation and maintenance of drill bits. Its ability to withstand high temperatures and wear makes it an excellent choice for ensuring drill bits perform optimally across various applications.