Benefits of High Concentration Color Masterbatch

2024-06-04

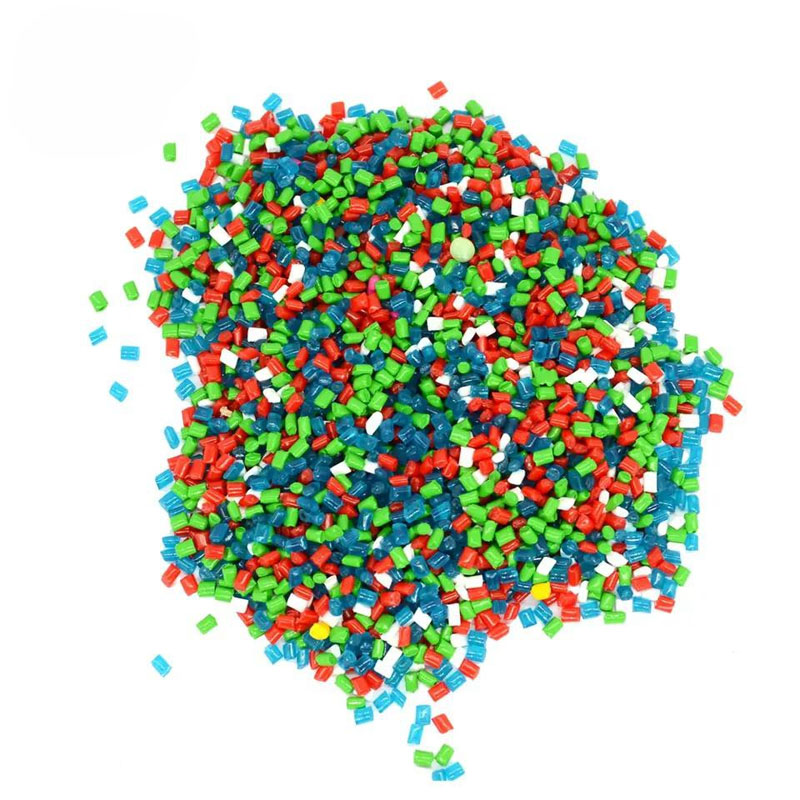

A high concentration color masterbatch is a type of additive used in the plastics industry to impart color to polymer resins. It is composed of a high concentration of pigments or dyes dispersed in a carrier resin, allowing for efficient and uniform coloring of plastic products. Here’s a comprehensive overview of high concentration color masterbatch, including its features, benefits, applications, considerations, and manufacturing process:

Key Features of High Concentration Color Masterbatch:

1. High Pigment Concentration:

- Contains a higher percentage of pigments or dyes compared to standard masterbatches, ensuring intense and vibrant colors.

2. Carrier Resin Compatibility:

- The carrier resin is selected to be compatible with the base polymer to ensure proper dispersion and processing. Common carrier resins include polyethylene (PE), polypropylene (PP), and polystyrene (PS).

3. Uniform Dispersion:

- Designed to disperse evenly throughout the polymer matrix, providing consistent color throughout the finished product.

4. Thermal Stability:

- Formulated to withstand the processing temperatures of various polymers without degrading or affecting the color quality.

5. Customized Formulations:

- Can be tailored to meet specific requirements, including color shade, opacity, and additional properties such as UV resistance and heat stability.

Benefits of High Concentration Color Masterbatch:

1. Cost Efficiency:

- The high concentration allows for smaller quantities to be used, reducing the cost per unit of colored product compared to lower concentration masterbatches or pre-colored resins.

2. Enhanced Color Quality:

- Provides more vibrant and uniform colors with greater consistency across batches.

3. Process Efficiency:

- Simplifies the manufacturing process by reducing the need for large inventories of pre-colored materials. It also allows for quicker color changes and more flexible production schedules.

4. Improved Performance:

- High-quality pigments and carrier resins enhance the physical properties of the final product, such as lightfastness, heat stability, and resistance to weathering.

Applications of High Concentration Color Masterbatch:

1. Injection Molding:

- Used to color a wide range of injection-molded products, including automotive parts, household goods, and packaging materials.

2. Blow Molding:

- Suitable for coloring bottles, containers, and other hollow parts produced by blow molding.

3. Film and Sheet Extrusion:

- Used in the production of colored films, sheets, and laminates for packaging, agriculture, and industrial applications.

4. Fiber and Textile Production:

- Applied in the coloring of synthetic fibers used in textiles, carpets, and nonwoven fabrics.

5. Pipe and Profile Extrusion:

- Used to color pipes, profiles, and other extruded products for construction, plumbing, and electrical applications.

Considerations When Using High Concentration Color Masterbatch:

1. Compatibility:

- Ensure that the carrier resin of the masterbatch is compatible with the base polymer to avoid processing issues and ensure optimal color dispersion.

2. Loading Levels:

- Determine the appropriate loading level (typically 1-5% by weight) to achieve the desired color intensity without affecting the mechanical properties of the final product.

3. Processing Conditions:

- Adjust processing parameters, such as temperature and screw speed, to accommodate the masterbatch and achieve uniform color distribution.

4. Quality Control:

- Implement rigorous quality control measures to ensure consistency in color and performance across different production batches.

Manufacturing Process of High Concentration Color Masterbatch:

1. Pigment Selection:

- High-quality pigments or dyes are selected based on the desired color, opacity, and performance characteristics.

2. Mixing and Compounding:

- The pigments are mixed with the carrier resin and other additives in precise proportions. The mixture is then compounded using twin-screw extruders to achieve uniform dispersion of the pigments.

3. Pelletizing:

- The compounded material is cooled and cut into small, uniform pellets, which are the final masterbatch product.

4. Quality Testing:

- The masterbatch undergoes various quality tests to ensure proper pigment dispersion, color consistency, thermal stability, and compatibility with the base polymer.

Conclusion:

High concentration color masterbatch is an efficient and cost-effective solution for coloring plastics, offering vibrant colors, uniform dispersion, and enhanced performance. It is widely used across various plastic processing methods and applications, providing flexibility and consistency in production. By understanding the key features, benefits, and considerations, manufacturers can effectively utilize high concentration color masterbatch to achieve their desired color effects and product quality.