Applications of Automotive Plastic Injection Mold

2024-03-01

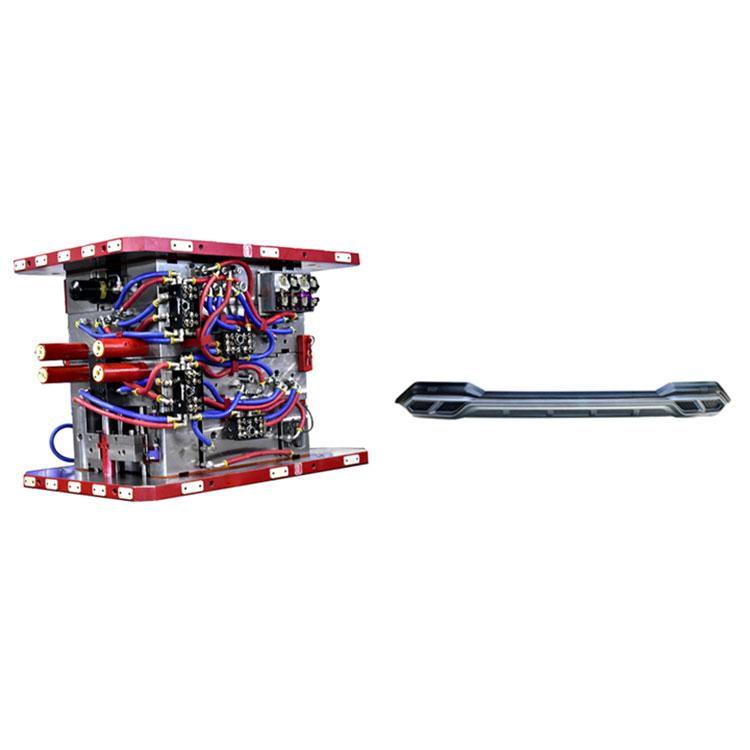

Automotive plastic injection molds are used to produce a wide range of plastic components that find applications throughout vehicles. Here are some common applications of automotive plastic injection molds:

1. Interior Components:

- Dashboard Components: Injection molds are used to produce parts of the dashboard, such as instrument panels, air vents, and glove box components.

- Door Panels and Trim: Interior door panels and various trim elements are often manufactured through injection molding.

2. Exterior Components:

- Bumpers: Both front and rear bumpers are often made using plastic injection molding due to the material's impact resistance.

- Body Panels: Some non-structural body panels, such as side panels and fenders, may be produced using injection molding.

3. Lighting Components:

- Headlamp Housings: Plastic injection molding is commonly used to manufacture headlamp housings and covers.

- Taillight Housings: Similarly, taillight housings and covers are often produced using injection molding.

4. Under-the-Hood Components:

- Engine Covers: Plastic injection molds are employed to manufacture engine covers and other components found under the hood.

- Air Intake Systems: Certain parts of air intake systems, like filter housings, can be made through injection molding.

5. Interior Trim and Seating:

- Seat Components: Various plastic components of car seats, such as trim and adjustment mechanisms, may be produced using injection molding.

- Interior Trim Pieces: Molded components for the interior, including trim pieces and panels, are common applications.

6. Electronic Housings:

- Control Modules: Housings for various electronic control modules and components within the vehicle are often created using injection molding.

7. Fluid Handling Components:

- Tanks and Reservoirs: Injection molding is used to produce fluid reservoirs, such as coolant and washer fluid tanks.

- Pipes and Connectors: Certain fluid-carrying components, like pipes and connectors, may be manufactured through injection molding.

8. HVAC System Parts:

- Ventilation System Components: Parts of the heating, ventilation, and air conditioning (HVAC) systems, such as air ducts and vents, can be produced using injection molding.

9. Interior and Exterior Trim:

- Handles and Knobs: Interior and exterior door handles, gear shift knobs, and other trim elements are commonly produced through injection molding.

These examples highlight the versatility of automotive plastic injection molds in producing a diverse array of components that contribute to the overall functionality, aesthetics, and safety of vehicles. The process is favored for its ability to create complex shapes with precision and efficiency, making it a key manufacturing method in the automotive industry.